Printing of µm structures with nano inks using a novel combination of high‐resolution plasma printing and subsequent rotogravure printing

Source: Preview Image: albln/iStockphoto

Abstract

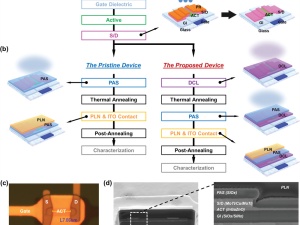

In this paper, we investigated reel‐to‐reel area‐selective microplasma treatment of polymer films using the plasma printing technique in combination with subsequent rotogravure printing. The aim was to explore whether and how the plasma printing pretreatment could contribute to increase print resolution with conductive nano inks on flexible polymer substrates. Substrate materials tested included films of biaxially oriented polyester and polypropylene. As the plasma process gas, a nonflammable mixture of 97% N2 and 3% H 2 was used. Novel microplasma sources developed during the course of this work achieved satisfactory plasma modification effects for the control of ink‐wetting patterns at process speeds of up to 3 m/min. In the case of biaxially oriented polypropylene (BOPP) film, this value was six times higher than the process speeds using previous microplasma sources. The reproduction accuracy achieved with these process parameters was typically better than 1.5% for structures with widths as low as 10 µm. Organic solvent and water‐based ink systems with silver and PEDOT:PSS as conductive components were tested in the rotogravure process following the area‐selective plasma pretreatment. In the combined plasma printing and gravure printing process, a resolution as good as 50 µm, was achieved using an aqueous PEDOT:PSS‐based ink. Conductive tracks produced on BOPP with this ink also passed the tape test for adhesion.

Full article:

Source: Preview Image: 501room/Shutterstock