Specific Electrical Contact Resistance of Copper in Resistance Welding

Abstract

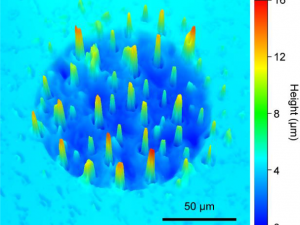

The electrical contact resistance (ECR) of copper (Cu-ETP R200, soft) contacts for resistance welding (RW) is characterized. ECR plays a major role in the RW process and provides local heat generation between the parts. A special determination method is used on different testing variants to observe the influence of contact pressure (two levels: 68, 155 MPa), contact temperature (20–550 °C), and surface parameters, like roughness or oxide layer thickness, on the specific electrical contact resistance (SECR). For each surface parameter, three different levels are investigated. The study shows decreasing SECR with higher mechanical load on the contact and a more complex behavior for increase in contact temperature. SECR shows a characteristic behavior for contact states near the temperature-dependent tensile strength of the base material for rough and clean surfaces, where SECR approaches toward zero. The variation of oxide layer thickness and surface roughness has a strong influence on the resulting SECR and both surface parameters show a strong coupling regarding their effects.

Source: Preview Image: helloSG/Getty Images