The Link between Ag‐Paste Rheology and Screen‐Printed Solar Cell Metallization

Abstract

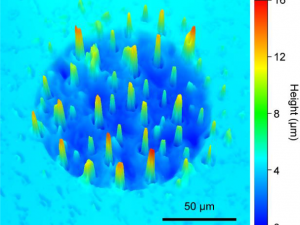

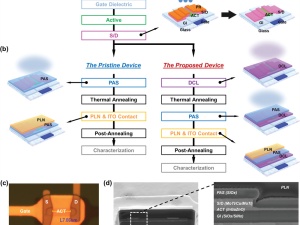

Today's photovoltaic production chain is moving into a material crisis as the use of silver for front‐side metallization of passivated emitter and rear contact solar cells remains a crucial requirement. The shared effort of the scientific and industrial community to further reduce Ag‐consumption as much as possible without compromising cell efficiency has become more challenging in recent years. Further improvements require a deep understanding on the paste‐screen interaction at narrow line widths. This study presents the impact of Ag‐paste rheology on fine line screen printing for screen openings between 15 and 24 µm at industrial printing speeds of up to 600 mm s−1. A clear trade‐off is there between maintaining a sufficient reproducibility of the screen printing process and achieving an optimized printed Ag‐electrode geometry, thus optimal Ag‐consumption. Further, a correlation between the work of adhesion at the paste–wire interface and the resulting deviation of the printed electrode height is discovered, highlighting the importance of an advanced screen optimization for the future of fine line screen printing. Finally, an easy to use method for analyzing the reproducibility of printed Ag‐electrode geometries even for lab‐scale data sets is presented.

Full article (Open Access):

Source: Preview Image: iStock.com/Milos-Muller