Revolutionizing Image Analysis in Metallography and Materialography with AI-Based Tools

Enhancing Accuracy and Efficiency in Microstructure Analysis

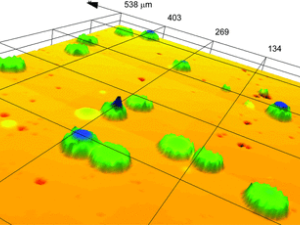

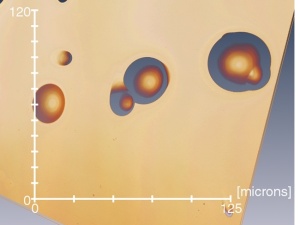

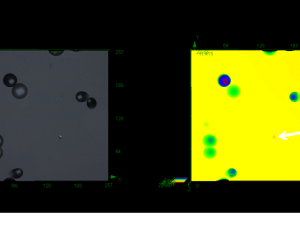

Artificial intelligence (AI) is rapidly transforming various aspects of our lives, including image analysis. In the field of metallography and materialography, AI-based image analysis tools are revolutionizing the way microstructures are examined. Traditional methods like thresholding have limitations in detecting specific structures, leading to inaccurate results. However, AI-powered algorithms leverage deep artificial neural networks to classify image areas independently, enabling easier and more accurate analysis.

This new approach is exemplified by the analysis of a metallographic sample. While conventional thresholding fails to distinguish grain boundaries from other elements, AI-assisted image analysis precisely identifies grain boundaries, grinding traces, and other objects of interest. Industrial imaging software, like PRECiV with TruAI deep-learning technology, offers instance and semantic segmentation methods, enabling the separation of touching objects and accurate background-foreground pixel classification.

To properly train a neural network for metallography and materialography, specialists must carefully label examples and verify training data. The training process involves augmenting data, selecting an optimal configuration, and validating the success of the training. This ensures accurate and reproducible image analysis, with experts verifying the results to minimize human bias.

By leveraging AI-based image analysis tools, professionals in metallography and materialography can achieve higher reproducibility, robust analysis, and improved efficiency in their work. The ability to automate complex tasks and accurately analyze microstructures opens up new possibilities for advancements in materials science and engineering.