Investigations on Corrosion Properties of Ultrasound-Enhanced Friction-Stir-Welded Aluminum/Dual-Phase Steel Joints

Abstract

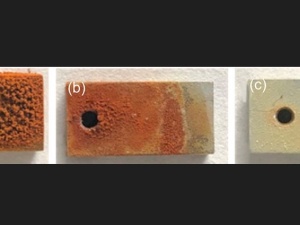

Friction stir welding (FSW) is a solid-state joining method that is suitable for joining dissimilar materials such as aluminum and steel due to its comparatively low process temperatures. Such hybrid joints are of great interest in view of lightweight construction efforts in various industrial sectors such as transportation. As the combination of different metals in hybrid structures may cause corrosion problems in the welding area because of the formation of a galvanic couple, the corrosion properties are investigated. This work also deals with the influence of additionally transmitted power ultrasound during friction stir welding on the joint properties of AA6061/DP600. Light microscopic analysis and radiographic results show differences in the amount and size of steel particles in the near-surface area of the joints depending on the used ultrasound power. Although the aluminum alloy and the dual-phase steel exhibit a Volta potential difference of about 0.8 V in scanning Kelvin probe (SKP) measurements, the measured corrosion current densities on different positions of the AA6061/DP600 joints in 0.5 m sodium chloride solution are only low and no enhanced Galvanic corrosion is observed. A distinct influence of the power ultrasound on the corrosion properties is not given.