Microstructure Analysis of Corrosion Resistance of Cast AlCu4Mg1 Alloy

In the automotive industry, the demand for aluminium alloys is growing every year and the requirements for these alloys are also increasing. This article discusses the evaluation of corrosion resistance of cast rods from alloy EN AW 2024. Experimental samples were laboratory subjected to a standard corrosion test according to CSN ISO 4287. Corrosive behavior was evaluated using light and electron microscopy. Furthermore, an analysis of the hardness of the material and the chemical composition was carried out. A map of corrosion-affected phases of the microstructure was also created, depending on time. This, together with the course of hardness, provides a comprehensive overview of the corrosion behavior of cast rods, which will serve as a starting point for further research in the field of barrier protection.

Introduction

The use of aluminum alloys in aerospace and automotive engineering products places increased demands on the corrosion resistance of materials to improve operational reliability and extend product life. The exclusion of possible causes of accidents and failures of automotive equipment (AE) due to the corrosion of aluminum alloys is based on comprehensive studies of climatic resistance of materials in their development and certification phase, rational design of AE products, excluding stagnant zones, as well as controlled operation, accompanied by timely identification and elimination of emerging corrosion damage.

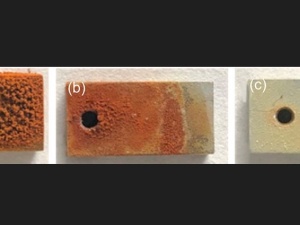

Commonly used methods for assessing the corrosion status of an AE product are visual inspection and nondestructive testing. For aluminum alloys, the formation of pitting (PC) and intergranular corrosion (IC) is the most critical. Pitting corrosion develops mainly in the direction of maximum deformation and is accompanied by peeling of individual metal particles so that it can be detected visually without the use of instrumental research methods. On the other hand, IC, in which destruction occurs along the grain boundaries deep into the semi-finished product, cannot be detected by the naked eye, so nondestructive methods are required. Not much work has been done to study the effect of the degree of sensitivity of alloys on MCC and the change in their mechanical properties after casting.

There is a need to study the influence of IC in climatic tests of structural aluminum alloys operating in conditions of increased aggressiveness of the atmosphere to change mechanical properties, which is necessary for the development of preventive measures aimed at improving reliable car operation. The aim of the article is to investigate the corrosion behavior of aluminum alloy 2024 in a salt environment with respect to the surface condition of the corrosion product in the alloy.

Introduction

The use of aluminum alloys in aerospace and automotive engineering products places increased demands on the corrosion resistance of materials to improve operational reliability and extend product life. The exclusion of possible causes of accidents and failures of automotive equipment (AE) due to the corrosion of aluminum alloys is based on comprehensive studies of climatic resistance of materials in their development and certification phase, rational design of AE products, excluding stagnant zones, as well as controlled operation, accompanied by timely identification and elimination of emerging corrosion damage.

Commonly used methods for assessing the corrosion status of an AE product are visual inspection and nondestructive testing. For aluminum alloys, the formation of pitting (PC) and intergranular corrosion (IC) is the most critical. Pitting corrosion develops mainly in the direction of maximum deformation and is accompanied by peeling of individual metal particles so that it can be detected visually without the use of instrumental research methods. On the other hand, IC, in which destruction occurs along the grain boundaries deep into the semi-finished product, cannot be detected by the naked eye, so nondestructive methods are required. Not much work has been done to study the effect of the degree of sensitivity of alloys on MCC and the change in their mechanical properties after casting.

There is a need to study the influence of IC in climatic tests of structural aluminum alloys operating in conditions of increased aggressiveness of the atmosphere to change mechanical properties, which is necessary for the development of preventive measures aimed at improving reliable car operation. The aim of the article is to investigate the corrosion behavior of aluminum alloy 2024 in a salt environment with respect to the surface condition of the corrosion product in the alloy.

Research material and methods

The composition of the alloy 2024[1] is given in Table 1. Macro-photographies of obtained samples were registered using a Canon EOS 1200D camera. Metallographic specimens were prepared by grinding on waterproof abrasive papers (P180, P320, P600, P1200, and P2000) and polishing using water suspensions of polycrystalline diamond with grain size of 3 and 1 µm. Microstructural investigation was performed by means of light microscopy (Olympus® LEXT™ OLS5000 3D measuring laser microscope with 4K scanning technology and Olympus MXU software). A Tescan VEGA3 electron microscope was used to examine the microstructure of the alloy by SEM. The chemical composition of selected phases precipitated in the microstructure was analyzed by energy dispersive X-ray spectroscopy (EDX) using an analyzer and SW Esprit 1.9. The Vickers hardness of the material according to the standard ČSN 42 0374 was measured at a load of 0.025 kgf.

Source: Preview Image: Vetta/iStockphoto