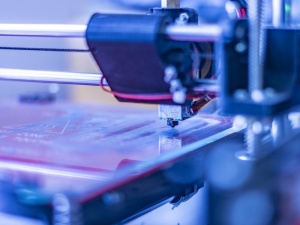

3D Printing Functionally Graded Porous Materials for Simultaneous Fabrication of Dense and Porous Structures in Membrane-Integrated Fluidic Devices

Abstract

3D printing provides access to complex multilevel architectures, though the capability to routinely print and integrate structures of controlled porosity is limited. Herein, grayscale digital light projection 3D printing of a polymerization-induced phase separation ink is introduced to directly 3D print functionally graded porous within a single layer from the same ink formulation. The structural properties of materials printed from a single ink are tuned from an effectively dense to a porous material with interconnected pores up to 250 nm. Heterostructures with the physically dense structure of porosity 0.8% and porous structures with up to 23% can be concurrently formed within a layer, with high spatial resolution inherent of this 3D printing technique. Materials with densities from 1.01 to 1.21 g cm−3 are 3D printed in a wicking device and show wicking rates (H2O) from complete diffusion blockage up to 4.5 mm h−1. Furthermore, a proof-of-concept membrane-integrated fluidic device is used for the elemental metal sensing of iron in soil. The presented single-step fabrication of functionally graded materials with pixel-based control within a single layer holds potential for manufacturing and integrating membranes or sorbents for environmental, biotechnology, and healthcare applications.