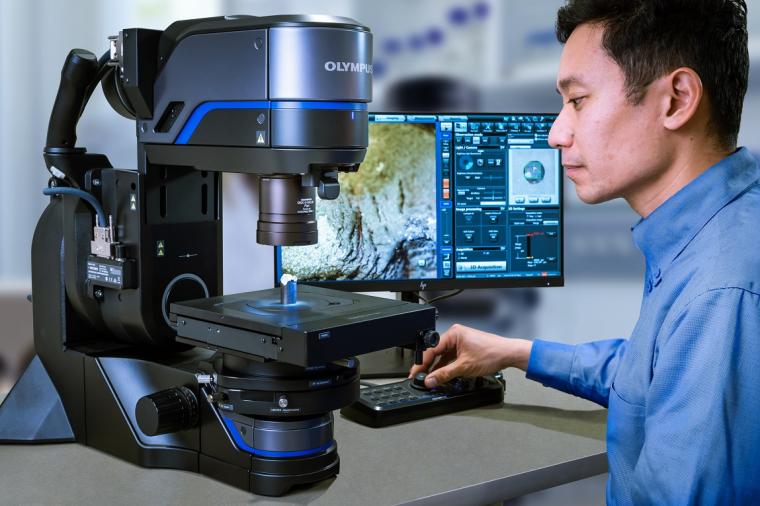

Confocal Laser Scanning Microscopy

One of the factors that contributes to the recent considerable reduction in size and high integration of electronics and other devices is miniaturization of the electronic components that make them up. In addition, new fine functional materials have been developed and widely used in industrial fields including the automobile, aviation, metal, and chemical industries. As a result, higher accuracy and resolving power are required for minute three-dimensional measurement of these components and materials. Although a variety of devices are available to satisfy these requirements, the confocal microscope is gathering attention as the device of choice for easy three-dimensional surface profile measuring in air, without touching the sample.

Confocal Optical System

Of the principles of laser scanning microscopes, the most basic is the confocal optical system. The confocal optical system has a pinhole with a circular opening at the position that conjugates the focal position of the objective lens (image forming position) to only detect light at the focused position. Although it is important to evenly illuminate a certain area for a ypical optical microscope, in the confocal optical system the light emitted from the point light source is radiated by the objective lens so that the light converges to one point on the sample. In general, a specific wavelength of laser light, which travels in a very straight line, is used as the point light source so that a large amount of light converges at one point. This reduces unnecessary scattered light from the environment and improves contrast compared with ordinary optical microscopes, which evenly illuminate the sample. The light reflects on the surface of the sample, goes back along the same optical path, is separated by the beam splitter, and converges on the pinhole. This optical system is able to obtain information from only the focal position as most of the reflected light from places other than the focal position is blocked at the pinhole. This means that the confocal optical system can act like a height sensor because of its narrow depth of focus while a conventional optical system cannot due it's large depth of field which includes unfocused data. In addition, while out of focus images from places other than the focal position are superimposed in an ordinary optical microscope, the confocal optical system blocks the reflected light from places other than the focal position at the pinhole, forming a perfectly focused clear image with good contrast. Although it is said that the diameter of the pinhole in the confocal optical system should be smaller than the divergence caused by the diffraction of the beam spot, this diameter is determined by balancing the sensitivity of the detector because the amount of light is reduced as the pinhole diameter is narrowed.

Two-Dimensional Scanning

As described above, the confocal optical system only obtains information in the direction of the optical axis. Therefore, some kind of two-dimensional scanner system orthogonal to the optical axis is required to convert data into images. Since this two-dimensional scanner system uses raster scanning to create an image, the accuracy of this scanning system directly determines imaging performance; accurate two-dimensional scanning is one of the most important technologies used in laser scanning microscopes. Scanning systems are generally divided into the sample scan method and the laser scan method. The sample scan method is performed by scanning the XY stage on which the sample is placed. This method allows the user to create an image of a large area without the need for optical scanning function, therefore, the confocal optical system will have a simpler structure. In addition, the XY stage can be accurately driven relatively easily. However, it takes a very long time to capture data and at a high resolving power it is necessary to drive the XY stage, including the sample for observation, with great precision. The laser scan method is performed by scanning a laser beam onto a sample in two dimensions, X and Y, using two scanning mechanisms. While the sample scan method is appropriate for capturing large waves on the sample surface, the laser scan method is ideal for capturing minute shapes. Most industrial laser scanning microscopes generally employ the laser scan method to put priority on image acquisition time. For example, an acousto-optic deflector (AOD), polygon mirror, or resonant galvano mirror is used in the X direction as the laser scanning mechanism because high-speed scanning is required. These scanning mechanisms are briefly introduced below.

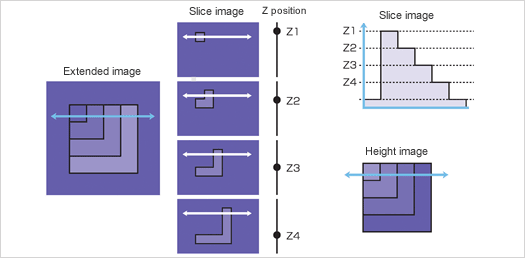

Three-Dimensional Images

In the confocal optical system, the Z position with the maximum intensity, that is, the brightest Z position indicates the height information of the sample surface at that point. Taking advantage of this fact, the height information of the sample can be captured by recording the Z position with maximum intensity. The figure below shows how height information is actually captured. In the same way as when capturing an extended focus image, move the sample and objective lens relative to each other and save the information on the brightest Z position for each pixel, where the maximum intensity can be obtained, while moving from height Z1 to Z2. This makes it possible to obtain the surface profile of the sample in the image acquisition area. A variety of analyses can be performed based on this information. This means that both intensity and height information can be obtained at the same time by capturing the maximum intensity value of each pixel into the extended image memory and the height at that time into the height image memory. This is the most significant characteristic of confocal microscopes that sets them apart from other microscopes.