Effect of Heat Treatment on the δ Phase Distribution and Corrosion Resistance of Selective Laser Melting Manufactured Inconel 718 Superalloy

Abstract

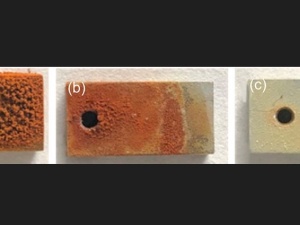

The microstructure, δ phase precipitating behavior and marine corrosion resistance of selective laser melted (SLM) Inconel 718 alloy were studied in two different heat treatment conditions. The SLM as-printed microstructures exhibited columnar grain structures with fine dendritic structure and recrystallization occurred after the heat treatments. The results of 6% FeCl3 immersion test and 3.5 wt% NaCl solution electrochemical corrosion test show that the corrosion resistance of the specimens with 950 °C solution + double aging (HT950) is better than that of 1050 °C solution + double aging (HT1050). Metallographic microscopy (OM) photographs show that due to the solution temperature is not high enough, the HT950 heat treated samples maintain columnar structures with irregular grain boundaries. Scanning electron microscopy (SEM) images indicated that it is the fine δ phase pinning effect that caused irregular grain boundaries. Meanwhile the HT1050 heat treated samples have a wide range of non-precipitated grain boundaries with few δ phase precipitation, and it will couple a “large cathode and small anode “ galvanic corrosion form, which will accelerate corrosion rate.

Full article:

Source: Preview Image: stable/Shutterstock