Engineering dislocation-rich plastic zones in ceramics via room-temperature scratching

Abstract

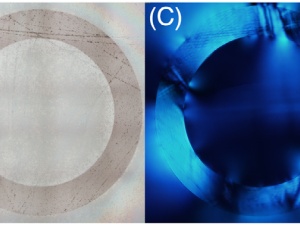

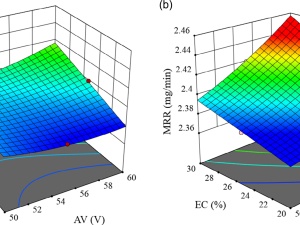

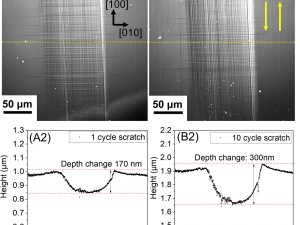

In this communication, we demonstrate a simple but powerful method to engineer dislocations into large plastic zones in various single-crystal ceramic materials via room-temperature scratching. By using a Brinell indenter with a diameter of 2.5 mm, we successfully produced plastic zones with a width and depth of ∼150 μm in a single scratch track, while the length of the scratch track can be arbitrarily long depending on the sample size. Increasing the number of repetitive scratching cycles increases the dislocation density up to ∼1013 m−2 without visible crack formation. The outlined experimental procedure is showcased on single-crystal SrTiO3, MgO, ZnS, and CaF2 to demonstrate the general applicability of this technique. In light of the increasing research interest in dislocation-tuned functional and mechanical properties in ceramics, our method will serve as a simple, fast, and robust technique to pave the road for scaling up the required large plastic zones for dislocation engineering in ceramics.

Full text:

Recommended Reading from our Editors

eBook 18: The Role of Ceramics in Transforming Industries:

Applications and Future Developments