Advanced Battery Technologies: Powering the Future

Energy Consumption and Needs

Concurrently with the expansion of renewable energy sectors, there has been a corresponding advancement in energy conversion and storage techniques. The characteristics of these emerging power generation methods have spurred the innovation and creation of diverse battery technologies – electrochemical energy storage devices that can collect and discharge energy through reversible chemical reactions.

At the forefront of battery development stands the lithium-ion battery (LIB), which first entered commercial markets in 1991. LIBs have undisputedly dominated the market and have become integral to our daily lives, seamlessly integrated into most electronic devices, from smartphones to electric vehicles.

Free eBook: Exploring Advanced Battery Technologies

Download our free eBook that discusses the increasing energy consumption in modern life, historically fueled by finite fossil fuels that have led to environmental issues and global warming. It emphasizes the need for transitioning to environmentally friendly alternative energy sources like hydroelectric, solar, geothermal, wind, nuclear, and biomass energy, which have spurred the growth of new industries.

Download nowWorking Principle

The working principle of a battery is based on a reduction/oxidation chemical reaction. In simple terms, there is an exchange of electrons between two poles, causing a change in the oxidation state of the involved materials. Both poles are immersed in an electrolyte, and each one reacts differently: the negative pole (anode) is oxidized due to the release of electrons, while the positive pole (cathode) is reduced due to the gaining of electrons.

This electron transfer occurs from the anode to the cathode through the circuit that needs to be powered. Ultimately, the cathode becomes full of electrons and is reduced, while the anode is oxidized. This process can be reversed by an external energy source, which is the process of charging the battery.

Types of Advanced Batteries

There are various types of batteries based on their construction, with the main classification being between disposable and rechargeable batteries. As mentioned earlier, the most widely used rechargeable batteries are LIBs due to their high efficiency. LIBs can store a substantial amount of energy and have an extended charge and discharge cycle, providing prolonged autonomy to devices. Additionally, LIBs are lighter than other rechargeable batteries of the same size, and their lifespan can range from 2 to 10 years.

Another type of battery gaining interest for its many advantages is aqueous zinc-ion batteries (ZIBs). Numerous claims have been made about the potential of ZIBs to replace LIBs, optimizing both charge density and manufacturing costs [1,2]. These batteries utilize Zn as the anode material and, similar to LIBs, operate through intercalation. This means that the same ion reacts at both the anode and cathode, traveling between the two through a liquid electrolyte. During discharge, the anode releases an ion into the electrolyte simultaneously as the cathode absorbs it, and this process is reversed during charging.

Zinc-ion batteries present an improvement in the manufacturing processes compared to lithium batteries. Lithium’s violent reactivity with water requires many production steps to be conducted in a highly controlled atmosphere, making the process costlier and more complicated. As water-based batteries, zinc-ion batteries do not face this restriction. Aqueous zinc-ion batteries (AZIBs) show promise for next-gen energy storage due to their safety, low cost, and non-toxicity [3]. In comparison to other battery technologies, AZIBs demonstrate advantages, such as high energy density, stable operation, environmental friendliness, economic viability, and simple assembly.

Main Challenges

The limited reserves and increasing prices of Li resources restrict their application in large-scale settings. Additionally, LIBs face safety hazards due to the explosive nature of organic electrolytes and the high cost of battery raw materials. Recently, extensive efforts have been undertaken to address these issues, including the design of anode and cathode structures, the development of new cathode materials, the optimization of electrolyte components, and the modification of current collectors [4]. Another significant challenge is that lithium metal anodes often experience shortened lifecycles marred by the formation of lithium dendrites during battery operation. The overgrown dendritic lithium poses a risk of short-circuiting the battery by penetrating the routine separator, leading to serious security incidents.

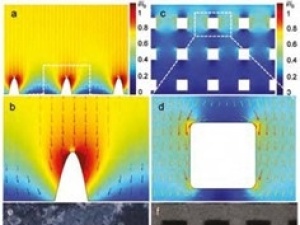

Dendrite formation is a common issue for both LIBs and ZIBs [5,6]. Dendrites are thin, tentacle-like metal filaments that develop on the battery electrode during charge and discharge cycles. Different topologies of Li and Zn dendrites infiltrate the electrolyte, causing problems, such as short circuits, overheating, and even fires. These formations can puncture the separator which prevents contact between the cathode and anode. Moreover, they escalate unwanted reactions between the electrolyte and the metal, accelerating battery failure.

In addition to dendrite growth, ZIBs also face challenges, such as cathode dissolution, electrolyte decomposition, hydrogen evolution, by-products, and corrosion issues. These problems lead to diminished electrochemical performance and even short circuits.

Research

Current issues in LIBs and ZIBs, as well as in other systems, are under extensive study, with diverse strategies being proposed. The primary focus of current research lies in the optimization of anode, cathode, and electrolyte materials [4–6].

For instance, Zhao et al. [7] introduced a novel polyvinylidene fluoride (PVDF) cation-selective separator to immobilize anions within the liquid electrolyte of a LIB. The construction of a dendrite-free Li anode was the key objective, and the separator, fabricated through a simple doctor-blading process of PVDF, exhibited outstanding performance.

In another approach, Zhang et al. [8] addressed the challenge of dendrite formation by exploring the construction of a 3D high-surface-area zinc anode. Increased surface area in a 3D conductive host helped reduce local current density and ensured a uniform distribution of interfacial charge. The authors combined 3D printing with electroless deposition to fabricate a conductive 3D nickel lattice (3D Ni) current collector. Subsequently, they achieved homogeneously electrodeposited Zn on the 3D Ni surface, resulting in the formation of 3D Ni–Zn lattices (3D Ni–Zn) as the anode for ZIBs. They successfully inhibited Zn dendrite formation in the 3D Ni–Zn anode, leading to a significant improvement in the electrochemical performance of batteries.

A different strategy was adopted by Yang et al. [9] to alleviate the problem of dendrite growth. They created a protective layer or solid electrolyte interphase (SEI) on the Zn electrode, preventing direct contact of Zn with water and inhibiting dendrite formation. They developed a polyanionic hydrogel SEI layer with multiple functionalities, demonstrating strong hydrogel-solid adhesion. This innovative hydrogel film served as an effective artificial protective layer for the Zn-metal anode. Consequently, the strategy of constructing a stable ionically conductive hydrogel-Zn interface with regulated Zn nucleation proved highly effective. The researchers anticipate that this approach could be a versatile protection method for metal electrodes across various battery systems.

Conclusion

The evolution of battery technologies plays a pivotal role in meeting the demands of the ever-growing need for energy consumption. LIBs have been instrumental in powering electronic devices, but their limitations, such as safety concerns and resource constraints, have led to a surge in research for advanced alternatives.

The challenges associated with LIBs and ZIBs, particularly dendrite formation, pose significant hurdles in achieving reliable and safe energy storage solutions. Addressing these challenges requires innovative strategies, as demonstrated by recent research efforts. Novel materials, protective layers, and advanced anode and cathode structures have been proposed to enhance battery performance and safety.

The ongoing research efforts to optimize anode, cathode, and electrolyte materials exemplify a steadfast dedication to surmounting current constraints, ultimately forging a path toward more sustainable energy storage solutions. As we delve deeper into the complexities of advanced battery technologies, the collective efforts of researchers worldwide showcase a commitment to powering the future with efficient, safe, and environmentally friendly energy storage systems. The journey towards unlocking the full potential of batteries continues, propelling us closer to a sustainable and resilient energy future.

Source: Preview Image: D3Damon/Getty Images