Profile method

Profile method versus the areal method

Measurement data acquired using the profile method is reliable since the data is obtained by directly tracing the surface with mechanical probes. Consequently, the profile method will likely remain a popular measurement technique for the foreseeable future. The disadvantages of the method are that it’s not suitable for soft material since the the contact probe can damage the surface being measured. In addition, since the measurement surface is evaluated based on the texture information obtained from a single section, the acquired data may not always reflect the irregularity characteristics of the overall surface area.

In contrast, most instruments based on non-contact three-dimensional measurement can work with soft materials without damaging the measurement surface. Also, three-dimensional data acquisition measures the surface characteristics over a large surface area, enabling users to characterize the orientation of parallel grooves and scratches that would be otherwise difficult to discern using the profile method. The areal method provides a lot of information and is effective at associating the required functionality of a surface, such as abrasion resistance, the adhesiveness between solids, and lubricant retention capability, with the surface parameters.

Profile method glossary

Primary profile curve

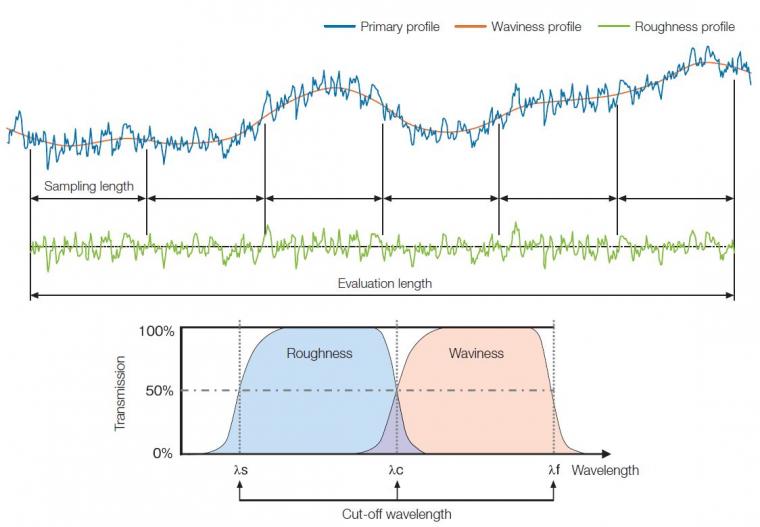

The curve obtained by applying a low-pass filter with a cutoff value of λs to the primary profile measured. The surface texture parameter calculated from the primary profile is referred to as the primary profile parameter (P-parameter).

Roughness profile

The profile derived from the primary profile by suppressing the long wave component using the high-pass filter with a cutoff value of λ c. The surface texture parameter calculated from the roughness profile is referred to as the roughness profile parameter (R-parameter).

Waviness profile

The profile obtained by sequential application of profile filters with cutoff values of λf and λc to the primary profile. λf cuts off the long wave component while the short wave component is cut off with filter λc. The surface texture parameter calculated from the waviness profile is referred to as the waviness profile parameter (W-parameter).

Profile filter

The filter for the isolation of the long and short wave components contained in the profile. Three types of filters are defined:

- λs filter: Filter designating the threshold between the roughness component and shorter wave components

- λc filter: Filter designating the threshold between the roughness component and waviness components

- λf filter: Filter designating the threshold between the waviness component and longer wave components

Cut-off wavelength

Threshold wavelength for profile filters. Wavelength indicating 50% transmission factor for a given amplitude.

Sampling length

The length in the direction of the X-axis used for the determination of profile characteristics.

Evaluation length

Length in the direction of the X-axis used for assessing the profile under evaluation.